Barrett Circle Jack

- Jun 21, 2022

- 3 min read

It took me several years of looking at old photographs of cable tool rigs to sort out what the curved tracks were that almost always sat on rig floors. I might have asked, for instance somebody like my friend, Robert from Oklahoma, but it's part of the fun to solve the mystery yourself. I guessed it had something to do with make up and break out of the bottom hole assembly and I was correct; it just took me awhile. These things are called Barrett Jacks, or more precisely, circle jacks.

On the left is a cable tool rig set to spud a well in Bolivia in 1923. OD of the bit is large suggesting they will run multiple casing strings as the well gets deeper, one string inside the other. These bottom hole assemblies (BHA) had to be heavy and the wrench tied off on the left of the photo is big, and heavy, and fits into the tool "slots," These different BHA components are spun up with a rope and a cat head, or a rope and calf wheel. To tight each component of the BHA (bit, bit sub, collars, jars and more collars) they used the Barrett circle joint as the diagram implies; one wrench was used as back up, the other wrench was use to tighten the connection as tight as possible by jacking the handle up and down on the right, much like a vertical tractor jack, or trac jack, only this one was horizontal and circular.

When the BHA needed to be broken out into individual components the circle track was simply reversed out and once the connection was loose they unscrewed it with a rope. Like a spinning chain on drill pipe, so to speak.

The circle jack was simply a precursor to make up and break out tongs on a rotary drive rig, right.

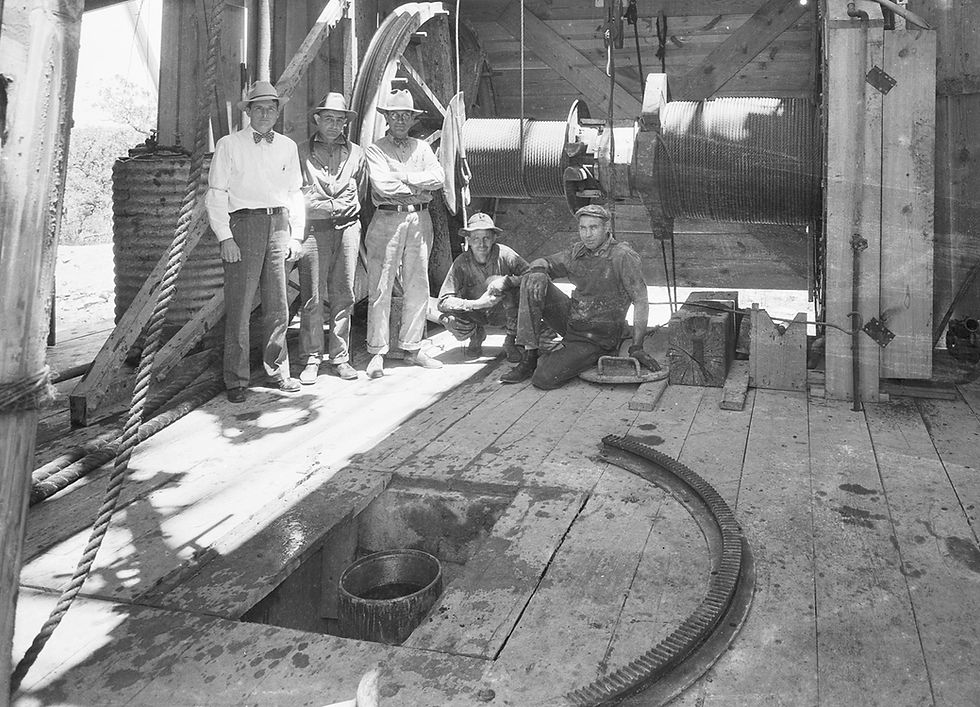

Circle jack tracks could be bolted down to the rig floor or more often they were heavy and just laid down on the floor as may have been required to either make something up, or break it out. In the photo above the circle jack track has been moved on to the side while the well is being bailed. The bit and BHA is tied back from the well while the bailer is run, and jack track is under the tie off on the right, laid over on its side.

On the right is another bailer run with the bit and BHA tied back...the jack track might be bolted to the rig floor.

So on a cable too rig the Barrett jack was used to jack stuff tight, then it was used to put a bind on something tight to break it out. Anything with a little torque in it that is whupped on hard enough with hammer with eventually pop loose.

The photo below is simply another photo of a bailer trip being made, with the track jack laying nearby on the rig floor.

All of this old school cable tool stuff was replaced, or revised in rotary table rigs where the pipe could be rotated via the rotary table.

Now days the rotary table has been replaced by the top drive and make up and break out tongs are replaced with something they call an iron roughneck, that envelopes the tool joint on drill pipe and makes it all up to precise torque. The driller now sits at his console in the drillers shack and does all this stuff remotely, via television cameras and joy sticks.

Big mama jama iron roughnecks on the left are used in top drive environments with 5 and 5 1/2 in. OD drill pipe, etc., lots of time on big floaters in deep water offshore.

Below is a little video of not some old, old school but an old school drill pipe connection work on a rotary rig with a top drive or a pipe spinner using make up and break out tongs. This is the shit I did until I was about 18, before I moved upstairs to a derrick hand, and before I graduated to driller, at 20 years old, sort of in charge of the whole thing, particularly not getting any of my hands, hurt. I never did.

Hands like these below are getting scarce; they deserve all of our upmost respect. I have re-published a comment from the previous post on temper screws, below, on circle jacks. Mr. Scott has been there, done that, and we should be honored to welcome his comment.

Comentarios